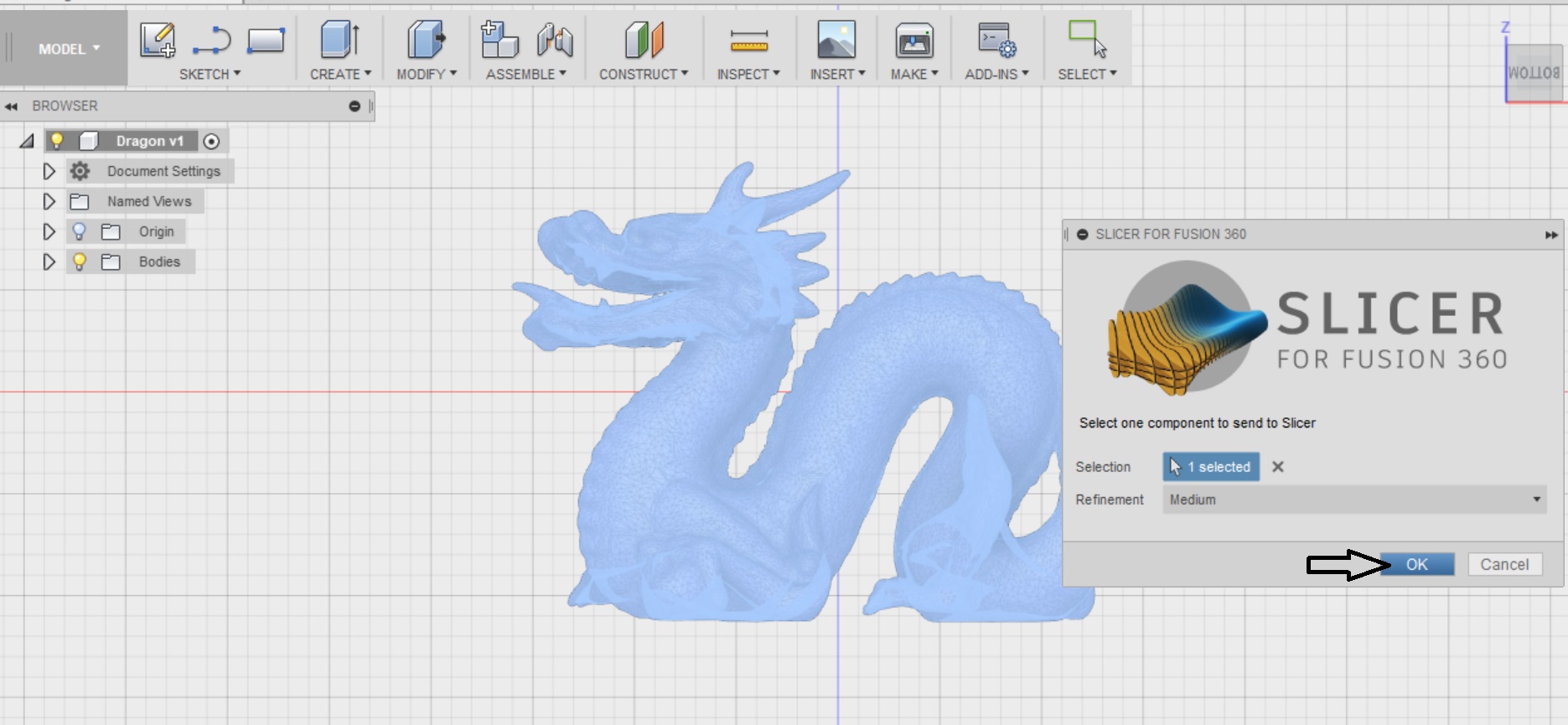

slice everything, inspect the toolpath and then export it, or, in Fusion’s language, “post” it to the machine. So at this point, we can actually go in and “generate the toolpath”, aka. Then choose your model and that’s the setup done!

So for best results, you’re probably going to have to tune some of these settings to your own machine, but for now I’m just using the default. Lastly, you’ve got the actual print and material settings, and the interesting thing is that it looks like those are shared between printers, so the configs that Autodesk are providing here are the same no matter what kind of printer you have. So the printer config itself defines what the machine is capable of and what its limits are, and that info is needed at the very start of the slicing process, and then the post script, at the very end of it, is basically your gcode output script, that translates the paths that the slicer has created into a file that the printer can read. Now, for each machine you get to choose a Post script, and that’s essentially the second part to your printer setup. And yes, it does already support dual-material prints, but since my Ultimaker 3 is kind of in a permanently clogged-up state, I wasn’t able to try that out yet. I’ve already got my Prusa MK3 in here, and that was a pre-made setup that Autodesk provide, they’ve got a few sample configurations already for things like the Anet A8, a bunch of Creality machines, the Prusas and the Ultimakers. To get into the slicer, you simply switch your workspace from “Design” to “Manufacture”, then you create a new setup, choose the machine you want to use, and that will automatically switch from a milling set up to an additive setup. So if you’ve ever used the CAM workflow in Fusion360, then this will feel very familiar. So now, there’s slicing in there as well, and it’s really neat to kind of have everything in one central location without having to export, import things back and forth between a bunch of different tools. Okay, I think this has been hardly a surprise to anyone: Fusion360 is already the preferred way of modelling parts for 3D printing for a huge number of you and they’ve also had really good CAM for milling and turning integrated into the software for quite a while. But should you completely switch over to just slicing through Fusion360? Let’s check it out. You can now slice your 3D prints directly in Fusion360, and their slicer actually has a few really nice features. stl, but is it worth using it in its current form?

Fusion360 now has a fully-featured slicer built right in! You can grab models directly from your design workspace without having to export as.

0 kommentar(er)

0 kommentar(er)